Introduction

3D printing has changed the way products are designed, tested, and manufactured. What once required large factories and complex machinery can now be done with a desktop-sized device. From prototypes and medical tools to hobby projects and industrial parts, 3D printing is becoming more accessible every year.

In this guide, we’ll explain how 3D printing works, the main types of printers, the materials used, and where this technology is applied in real life — all in clear and simple language.

What Is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating physical objects from a digital file by building them layer by layer.

Unlike traditional manufacturing, which often cuts or removes material, 3D printing:

-

Adds material gradually

-

Builds objects from the bottom up

-

Follows a digital 3D model

This layer-by-layer approach allows for precise designs and complex shapes that would be difficult to create using traditional methods.

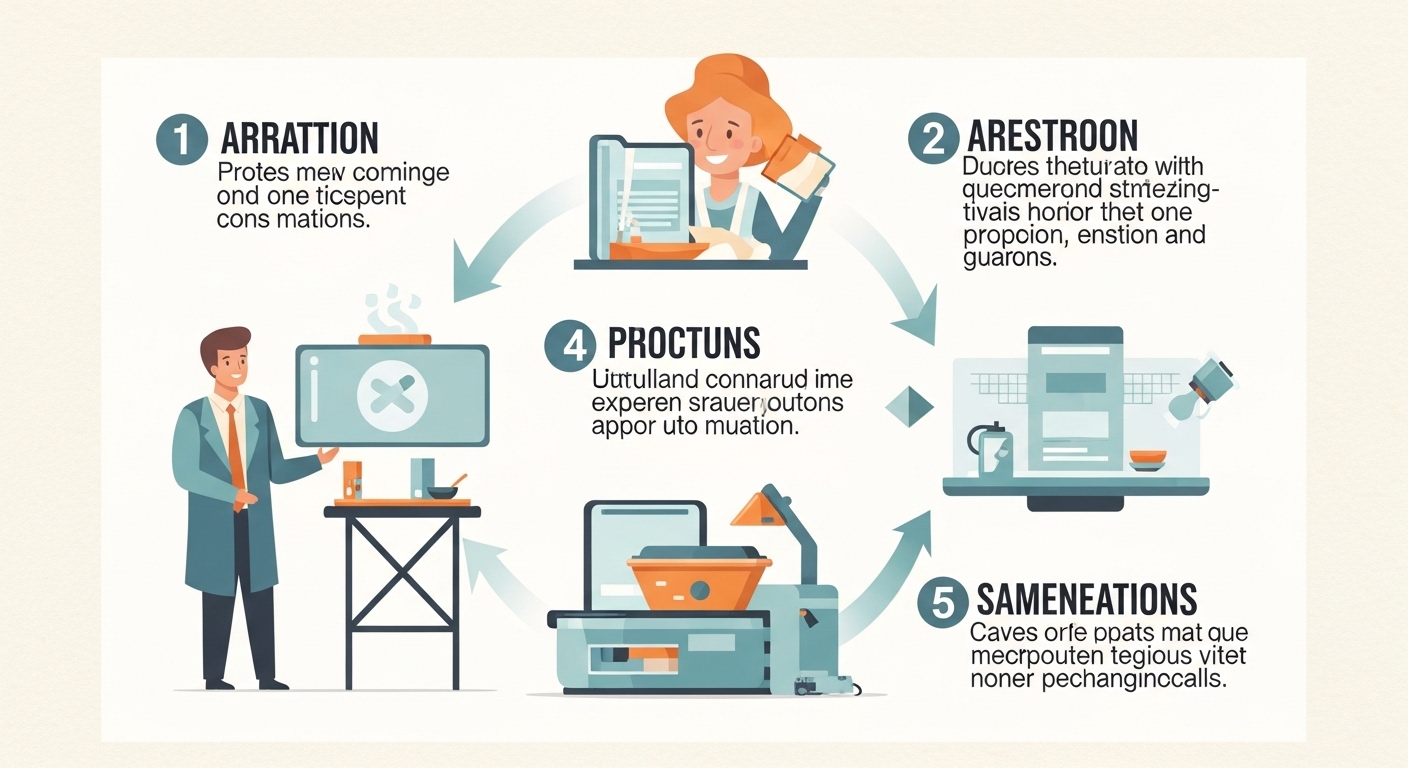

How Does 3D Printing Work?

Although different printers use different technologies, the basic process follows these steps:

1. Creating a Digital Model

Everything starts with a 3D design file. This file is created using computer-aided design (CAD) software or downloaded from a 3D model library.

The digital model defines:

-

Shape

-

Dimensions

-

Internal structure

-

Surface details

2. Slicing the Model

Before printing begins, special software converts the 3D model into thin horizontal layers. This process is called slicing.

The slicing software:

-

Breaks the model into hundreds or thousands of layers

-

Generates instructions for the printer

-

Determines printing speed and material usage

3. Printing Layer by Layer

The printer then follows the instructions and builds the object:

-

A material (plastic, resin, or metal) is deposited

-

The first layer is created on the build platform

-

Each new layer is added on top of the previous one

-

The object gradually takes shape

This process continues until the final object is complete.

4. Post-Processing

After printing, the object may need finishing steps such as:

-

Removing support structures

-

Cleaning excess material

-

Sanding or polishing

-

Curing (for resin prints)

Not all prints require heavy post-processing, but some applications demand higher surface quality.

Main Types of 3D Printing Technologies

There are several types of 3D printing methods. Here are the most common ones:

1. FDM (Fused Deposition Modeling)

This is the most popular and affordable type of 3D printing.

How it works:

-

A plastic filament is heated

-

The material is extruded through a nozzle

-

Layers are built as the plastic cools and hardens

Commonly used for:

-

Prototypes

-

Educational projects

-

Hobby printing

2. SLA (Stereolithography)

SLA printers use liquid resin that hardens when exposed to light.

How it works:

-

A laser or light source cures liquid resin

-

Each layer solidifies before the next is added

Commonly used for:

-

Detailed models

-

Dental and medical applications

-

Jewelry design

3. SLS (Selective Laser Sintering)

This method uses powdered material and a laser.

How it works:

-

A laser fuses powder particles together

-

Layers of powder are added and fused repeatedly

Commonly used for:

-

Functional prototypes

-

Industrial parts

-

Complex mechanical components

Materials Used in 3D Printing

Different printers use different materials. Some common options include:

-

PLA (biodegradable plastic)

-

ABS (durable plastic)

-

Resin

-

Nylon

-

Metal powders

-

Composite materials

Material selection depends on:

-

Strength requirements

-

Flexibility

-

Heat resistance

-

Surface finish

Advantages of 3D Printing

3D printing offers several benefits compared to traditional manufacturing:

-

Rapid prototyping

-

Reduced material waste

-

Ability to create complex shapes

-

Customization and personalization

-

Lower production costs for small batches

It is especially useful when producing limited quantities or unique items.

Limitations of 3D Printing

Despite its advantages, 3D printing also has limitations:

-

Slower production for large volumes

-

Limited material strength in some consumer models

-

Surface finish may require additional work

-

Equipment costs for industrial systems

Understanding these limitations helps users choose the right manufacturing method.

Real-World Applications of 3D Printing

Today, 3D printing is used in many industries:

-

Healthcare (prosthetics, dental models)

-

Automotive prototyping

-

Aerospace components

-

Education and research

-

Architecture models

-

Consumer product design

It is not replacing traditional manufacturing entirely, but it is complementing it in innovative ways.

Is 3D Printing Suitable for Beginners?

Yes. Many entry-level printers are designed for:

-

Students

-

Hobbyists

-

Designers

-

Small businesses

However, beginners should consider:

-

Learning basic 3D modeling

-

Understanding printer calibration

-

Following safety guidelines

With proper setup and maintenance, 3D printing can be accessible and educational.

Conclusion

3D printing works by transforming digital models into physical objects through a layer-by-layer process. By combining software design, precise hardware, and specialized materials, this technology enables the production of complex and customized items.

As the technology continues to develop, 3D printing is becoming more efficient, affordable, and widely used across industries. Whether for education, design, or manufacturing, it represents an important step in modern production methods.

Frequently Asked Questions

1. How long does 3D printing take?

Printing time depends on the object’s size, complexity, and printer type. Small objects may take a few hours, while larger ones can take much longer.

2. Is 3D printing expensive?

Entry-level printers are relatively affordable. Industrial systems are more costly and are used for specialized applications.

3. Can 3D printers print metal?

Yes, certain industrial printers use metal powders and laser technology.

4. Is 3D printing environmentally friendly?

It can reduce material waste compared to traditional methods, but environmental impact depends on materials and energy use.